The air conditioner compressor is a vital component of any cooling system, responsible for circulating refrigerant and driving the heat exchange process that keeps your spaces cool and comfortable. With several types of compressors available – each designed to suit different applications and efficiency needs – it’s essential to understand their unique features and functions.

So, in this article, we’ll break down the various air conditioner compressor types, explain how they work, their benefits, and how to make an informed choice for your cooling system.

Five Types of Air Conditioner Compressors

Let’s start by looking at the various types of compressors:

Reciprocating compressors: The reciprocating compressor is one of the oldest designs operating similarly to the compressors used in refrigeration. It relies on a piston moving up and down within a cylinder to compress the refrigerant. While the piston mechanism is prone to wear over time, the capacity to integrate up to eight cylinders does enhance its overall efficiency.

Scroll compressors: Scroll compressors represent a more modern design, featuring a stationary scroll at the centre and a second scroll rotating around it. This mechanism compresses the refrigerant and directs it towards the centre. With fewer moving components than reciprocating compressors, scroll compressors tend to offer greater reliability.

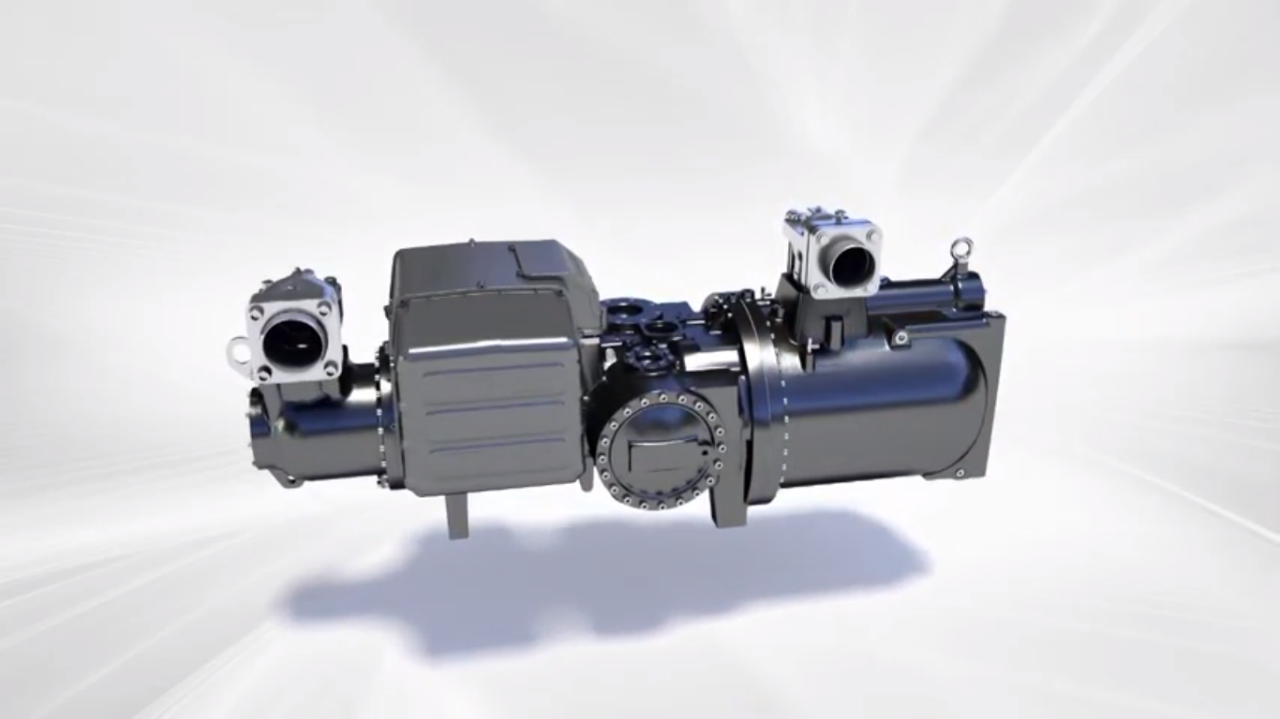

Screw compressors: Screw compressors are commonly used in large commercial settings where substantial cooling and air circulation are required. They employ interlocking helical rotors to compress refrigerant as it moves from one end to the other. While highly efficient and dependable, their cost may render them less practical for smaller-scale applications.

Rotary compressors: Rotary compressors use a rotational mechanism to compress refrigerant. Equipped with an accumulator to evaporate liquid refrigerant before it enters the compression chamber, these compressors are known for their quieter operation and greater energy efficiency than reciprocating models.

Centrifugal compressors: Centrifugal compressors are used in the largest HVAC systems, employing centrifugal force and an impeller to compress refrigerant. These units are powerful and well-suited to extensive cooling demands, making them a preferred choice for large-scale applications.

How Air Conditioner Compressors Work

An air conditioning compressor plays a vital role in the functionality of an air conditioning system by pumping refrigerant throughout the unit. It is essential for enabling the heat pump to operate effectively. Located within the condenser unit, the compressor is responsible for compressing refrigerant vapour to facilitate the cooling process.

To unpack it in more detail, the compressor transfers heat from the refrigerant (the cooling liquid) to the condenser, which expels the heat from the air. By compressing the refrigerant into a smaller volume, the compressor increases its pressure and temperature, enhancing the system’s energy efficiency. The process reverses during cooling, lowering the temperature after heat removal has occurred.

Beyond managing heat transfer, compressors also contribute to cooling by promoting evaporation. This involves extracting moisture from indoor air and converting it into water vapour, which is then expelled outside. This mechanism helps maintain comfort by removing excess humidity from indoor spaces.

Benefits of Air Conditioner Compressors

Let’s now look at some of the benefits of air conditioner compressors:

Enhanced comfort and reliability: A high-quality AC compressor ensures dependable performance, maintaining consistent cooling even during extreme heat. They are designed for durability and longevity, providing peace of mind and a steady supply of cool air during summer’s peak. The high-quality models often require less frequent maintenance, which means reduced repair costs and less inconvenience over the system’s lifespan.

Quieter operation for a tranquil environment: Modern air conditioning compressors are built with sound-reduction technologies that prioritise quiet operation. By minimising noise output, these compressors create a calm and undisturbed indoor environment. This feature is especially beneficial in homes, offices, or other spaces where concentration, rest, or relaxation is essential. Quiet systems also make air conditioning more compatible with open-plan living or workspaces, ensuring cooling comfort without intrusive background noise.

Additional advantages: High-efficiency AC compressors often include advanced diagnostic features that monitor performance and alert users to potential issues. These smart systems simplify maintenance and reduce the likelihood of sudden breakdowns. Many of these compressors come with extended warranties, offering long-term protection and added value for the investment. They also support compatibility with smart thermostats, allowing for remote control and customised cooling schedules, further enhancing energy efficiency and convenience.

Factors to Consider When Choosing a Compressor

Air compressors are essential for various industries, including manufacturing, pharmaceuticals, chemical processing, and food and beverage production. Choosing the right compressor system for a specific application can be complex due to the variety of technologies available. To make an informed decision, several factors must be considered. The variety of AC compressors ensures there’s a suitable option for every need, from the energy-efficient rotary compressor ideal for residential use to the robust screw compressor designed for expansive commercial spaces. Understanding the unique attributes of each type can help guide you to the best solution for your cooling system.

These are a few other key considerations to keep in mind:

Choosing oil-free or oil-injected: The choice between oil-free and oil-injected compressors depends on industry requirements. Oil-free compressors are ideal for sectors like food and beverage, pharmaceuticals, and electronics, where air quality is critical. Oil-injected compressors mix oil with air for sealing, lubrication, and cooling, making them suitable for industries where minimal oil content is acceptable. While oil-injected systems may have lower upfront costs, oil-free compressors often have reduced lifecycle costs, as they require less filtration, lower energy consumption, and simpler maintenance.

Choosing the right pressure and flow rate: Selecting the correct compressor size is vital. A system that’s too small won’t meet your needs, while one that’s too large wastes energy. Pressure, measured in bars or psi, determines the system's ability to perform specific tasks. Ensure your compressor provides sufficient pressure with a margin for pipeline or ancillary pressure drops. Rotary screw compressors work well for medium pressures, while reciprocating models are ideal for pressures above 20 bar. Flow rate, measured in cubic metres per hour or cubic feet per minute, indicates the air volume the compressor can handle. Technologies like centrifugal compressors are efficient for high flow rates, whereas rotary screw or tooth compressors are better for lower flow demands.

Choosing the right noise level: Modern air compressors often include noise-reduction systems to create a more comfortable work environment. Many models feature sound enclosures or canopies to minimise noise, often reducing levels to 80 dBA or less.

Choosing the right cooling system: Proper cooling prevents compressors from overheating. Systems can be air-cooled or water-cooled, with air dryers added downstream to reduce air temperature and moisture content. Water-cooled compressors are more energy-efficient, while air-cooled systems require adequate ventilation for effective operation.

Choosing the right design: If space is limited, consider compact, plug-and-play compressors. These units integrate essential components like filtration, cooling, lubrication, control panels, and remote monitoring systems into a small footprint. Designed for easy installation, they are ideal for industrial plants with spatial constraints.

About Daikin

Daikin is the global pioneer and leader in the HVAC and refrigeration industry, driving innovation and sustainability across an extensive product range, including air conditioning units, grills, chillers, VRV systems, air handling units (AHUs), fan coil units (FCUs), controls, pumps, and comprehensive service and parts support. Through this, Daikin meets and exceeds the needs of residential, commercial, and industrial applications.

Belief in the infinite potential of people is at the core of our philosophy, and we are constantly working towards a future where comfort and environmental responsibility coexist harmoniously. We are proud to employ over 98,000 people, operating in over 170 countries with a global network of 115 factories. By safeguarding the future of our planet’s air, we are committed to enhancing the environment for future generations. Contact Daikin today to learn more about our state-of-the-art air conditioning systems.